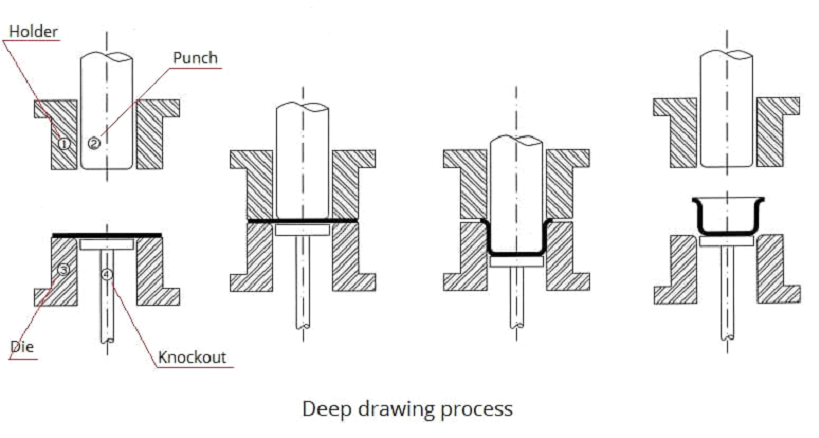

Deep Drawing

Deep drawing is a sheet metal forming technique in which a sheet metal blank is mechanically pulled radially into a forming die. As a result, it's a material-retention shape modification process.

When the depth of the drawn part exceeds its diameter, the procedure is called "deep" drawing. This is accomplished by the use of a series of dies to redraw the part. Due to the material retention property, the flange region (sheet metal in the die shoulder area) experiences radial drawing stress and tangential compressive stress.

Flange wrinkles are caused by compressive stresses (hoop stresses) (wrinkles of the first order). The use of a blank holder, whose purpose is to permit controlled material flow into the die radius, can help to avoid wrinkles

We provide both Deep Drawing and Sheet Metal Stamping Services as per the requirement of the customers.

CONTACT US FOR MORE INFORMATION.

Tool Designing And Manufacturing.

We design tools and offer complete system solutions. We use skilled engineering in accordance with manufacturing standards, which includes the analysis, planning, design, building, and use of tools, methods, and procedures to boost production productivity.

This solution provides our experience and infrastructure to help clients reach their delivery deadlines. Understanding the client's products, manufacturing requirements, and infrastructure are all part of tool design process. This process is followed in the solid modelling of the product, tooling, and the fabrication of manufacturing drawings. We provide tool design services for the following applications:

-- Press tools-- Multi-forming Press Tools

CONTACT US FOR MORE INFORMATION